PLC Automatic Floor Tile Making Machine Artificial Stone Production Line

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30Days |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Dimension(L*W*H): | 7000*1000*1800mm | Type: | Artificial Stone Product Line |

|---|---|---|---|

| Product Name: | Veneer Stone Production Line | Control System: | PLC |

| Product Name: | Wet Cast Machinery | Style: | Full Auto |

| Color: | Blue | Voltage: | 220V |

| Highlight: | Wet Cast Auto Floor Tile Making Machine,PLC Automatic Floor Tile Making Machine |

||

Product Description

Product Description:

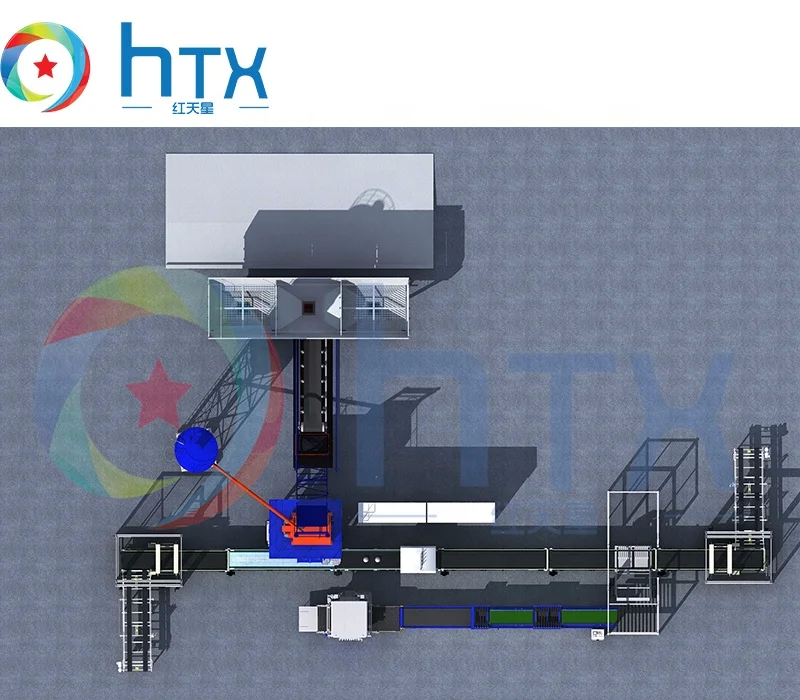

The Veneer Stone Production Line is a fully automatic wet cast machinery designed to produce concrete retaining blocks, cultured stones, and wall panels. This line has a PLC control system and a blue color, and it is perfect for anyone looking for a reliable and efficient concrete retaining block casting machine, cultured stone making machine, and wall panel production machine.

The Veneer Stone Production Line is designed to provide maximum efficiency and accuracy with its automatic feature. The PLC control system ensures precise measurements and a consistent quality of stones produced. The blue color adds a stylish look to the production line.

This production line is ideal for anyone looking for a reliable and efficient way to produce concrete retaining blocks, cultured stones, and wall panels. The fully automatic feature ensures maximum efficiency and accuracy, while the PLC control system provides precise measurements and a consistent quality of stones produced.

The Veneer Stone Production Line is the perfect choice for anyone looking for a reliable and efficient concrete retaining block casting machine, cultured stone making machine, and wall panel production machine.

Features:

- Product Name: Veneer Stone Production Line

- Production Capacity: 1000-1500m2

- Control System: PLC

- Weight: 2000kg

- Color: Blue

- Concrete Dosing System: Concrete Dosing System

- Cultured Stone Making Machine: Cultured Stone Making Machine

Technical Parameters:

| Parameters | Values |

| Production Capacity | 1000-1500 m2 |

| Weight | 2000 kg |

| Voltage | 220V |

| Style | Full Auto |

| Type | Artificial Stone Product Line |

| Feature | Automatic |

| Product Name | Veneer Stone Production Line |

| Wet Cast Machinery | Yes |

| Control System | PLC |

| Color | Blue |

| Wall Panel Production Machine | Yes |

| Floor Tile Making Machine | Yes |

| Concrete Dosing System | Yes |

| Vibration Table | Yes |

| Curing Room | Yes |

![]()

![]()

![]()

![]()

![]()

Applications:

The Wet Cast Machinery with the brand name of HTX is a type of Artificial Stone Product Line with the model number of HTX-P-01, which is certified by POSI CERTIFICATE. This product line is developed and manufactured in HENAN. And this product line is with a PLC control system, and its dimension is 7000*1000*1800mm. With this product line, it can help to produce wall panel production machine and cultured stone making machine, with a production capacity of 1000-1500m2.

Customization:

- Brand Name: HTX

- Model Number: HTX-P-01

- Place of Origin: HENAN

- Certification: POSI CERTIFICATE

- Product Name: Wet Cast Machinery

- Style: Full Auto

- Product name: Veneer Stone Production Line

- Production Capacity: 1000-1500m2

- Feature: Automatic

- Keywords: wall panel production machine, Concrete precast machine line, Concrete precast machine line

Support and Services:

We provide technical support and service for our Veneer Stone Production Line.

We have a team of highly trained technicians and engineers who are available to answer any technical questions you may have and provide advice on the best way to use the product.

We also offer a range of services, such as installation, maintenance, and repair. We can provide on-site support for repairs and maintenance, as well as remote support for any technical issues you may have.

If you have any further questions about our Veneer Stone Production Line, please do not hesitate to contact us.