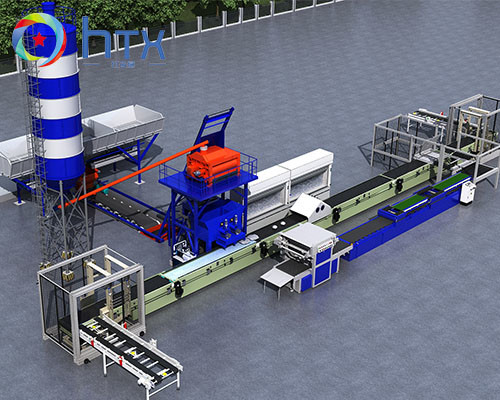

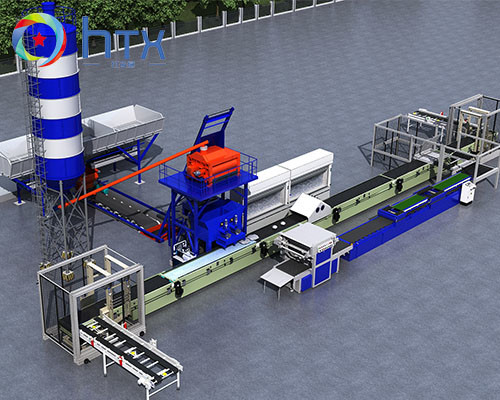

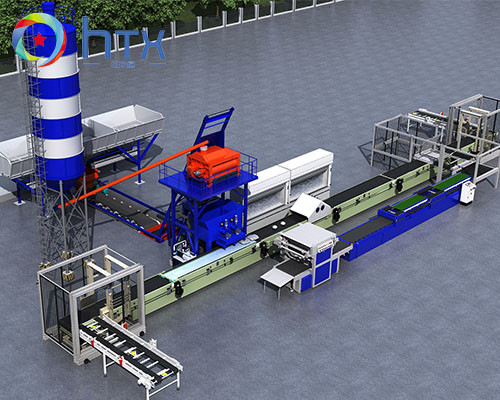

Product Line For Artificial Stone Labor Saving Production Improving

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stone Production Line | Production Capacity: | 1000-1500m2 |

|---|---|---|---|

| Voltage: | 220V | Weight: | 2000kg |

| Feature: | Automatic | Color: | Blue |

| Product Name: | Wet Cast Machinery | Dimension(L*W*H): | 7000*1000*1800mm |

| Whether It Can Be Customized: | Customizable | ||

| Highlight: | Labor Saving Artificial Stone Production Line,Production Improving Artificial Stone Production Line,Product Line For Artificial Stone |

||

Product Description

Product Description:

HTX machinery is not only many kinds of molds manufacturer also have product line about artificial stone molds, plastic molds, rubber molds and silicone molds.

Configuration of the artificial stone production line:

1. Mold (cultural stone mold, mold tray, drying rack)

- Color matching room (requires iron oxide pigment, spray gun and air compressor)

- Production equipment (there are simple production lines, semi-automatic production lines, and fully automatic production lines)

- Drying room

- Forklift

We will offer detailed installation and operation manual for reference for installation and debugging.

![]()

1. Simple production line about artificial stone mold

For simple production line, it only need mixer, vibration table then can start to produce the stone. Also if you need can add demoulding machine. This is a low-cost project. Most used of plastic paving mold.But more staff are required to participate.

- Semi auto production line for artificial stone mold

The price of semi-automatic production line is not as high as that of automatic production line, and the output is more advantageous than that of simple production line.The price will also be higher than that of the simple production line, but there will be less manpower.

- Auto artificial stone production line

Auto artificial stone production line is suitable for different silicone molds, pvc soft technology molds, rubber molds and plastic molds. Size range from 200x200mm to 1500x1500mm, available for producing the artificial stone both for wall and floor paving, 3D wall panel, terrazzo floor tile, etc. The least manpower and the fastest production efficiency.

Technical Parameters:

| Parameter | Value |

|---|---|

| Color | Blue |

| Product Name | Veneer Stone Production Line |

| Control System | PLC |

| Voltage | 220V |

| Type | Artificial Stone Product Line |

| Production Capacity | 1000-1500m2 |

| Feature | Automatic |

| Dimension(L*W*H) | 7000*1000*1800mm |

| Weight | 2000kg |

| Concrete precast machine line | Yes |

| Wall panel production machine line | Yes |

Applications:

HTX-P-01 Veneer Stone Production Line is a high end artificial stone product line made in HENAN, certified by POSI CERTIFICATE. It is designed with a full auto style and a blue color. The production line is equipped with a PLC control system, a concrete dosing system, a concrete precast machine line, and a wall panel production machine. It can help to cast concrete products in a wet environment and produce high quality veneer stone products with great efficiency and accuracy.

Customization:

HTX proudly presents the HTX-P-01 Veneer Stone Production Line, an automated and reliable solution for any wet cast machinery and veneer stone production line. Certified with POSI CERTIFICATE, this full auto artificial stone production line is made for both commercial and industrial use. Featuring a voltage of 220V, a blue color and a weight of 2000kg, this cultured stone making machine ensures a consistent production of high-quality veneer stones.

Support and Services:

We provide technical support and services for our Veneer Stone Production Line. Our customer service team is available to answer any questions you may have and to provide technical advice and troubleshooting. We provide on-site installation, training, and maintenance services to ensure your production line runs smoothly and efficiently.

We also provide round-the-clock support for our Veneer Stone Production Line. Our team is always available to help with any issues you may be experiencing. We can also help you optimize your production line for better efficiency and cost savings.

We stand behind the quality of our Veneer Stone Production Line and offer a full satisfaction guarantee. If you're not completely satisfied with your purchase, we will work with you to resolve any issues or provide a full refund.