Concrete Dosing System Veneer Stone Production Line With 1000 -1500m2 Capacity

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Style: | Full Auto | Type: | Artificial Stone Product Line |

|---|---|---|---|

| Product Name: | Veneer Stone Production Line | Weight: | 2000kg |

| Product Name: | Wet Cast Machinery | Production Capacity: | 1000-1500m2 |

| Dimension(L*W*H): | 7000*1000*1800mm | Color: | Blue |

| Highlight: | Concrete Dosing System Stone Production Line,Full Auto Artificial Stone Production Line,Veneer Stone Production Line 1000m2 |

||

Product Description

Product Description:

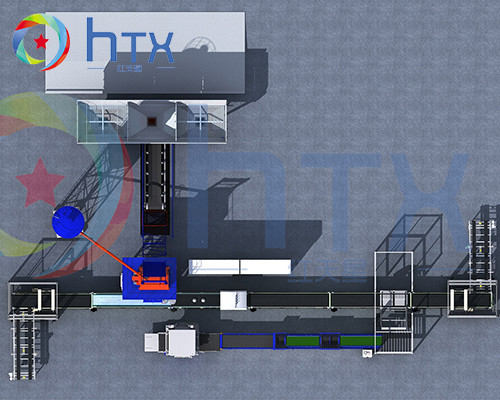

The Veneer Stone Production Line is a full-automatic wet cast machinery that is specially designed to produce floor tiles. It is featured with an automatic system and powered by 220V voltage to provide blue-colored floor tiles with a high production rate. This kind of floor tile making machine is very easy to operate and can greatly reduce the production cost and time. With the latest technology, the Veneer Stone Production Line ensures the production of high-quality and durable floor tiles. It is also an efficient and cost-effective system that can be used for a long period of time. This floor tile making machine is also a great choice for those who want to create stunning and unique designs for their interior and exterior areas.

Features:

- Product Name: Wet Cast Machinery

- Dimension(L*W*H): 7000*1000*1800mm

- Type: Artificial Stone Product Line

- Weight: 2000kg

- Control System: PLC

- Paver block making machine: Yes

- Veneer stone production line: Yes

- Paver block making machine: Yes

Name Model Specification Size

(mm)

Power

(Kw)

Capacity

(m2/day)

Weight

(Kg)

Artificial stone production line HTX-P-01 Hydraulic driving;Auto feeding;

vibrating and timing feeding

7000*1000*1800 12.7 1000-1200 2000 Wet Cast Machinery HTX-P-01A Full Auto,timing feeding and vibration, weighing system; 12000*1000*2000 9.1 800-1000 2000

Applications:

HTX-P-01 Wet Cast Machinery is a brand-new Veneer Stone Production Line developed by HTX. It is designed with advanced technology, which adopts a Concrete Dosing system to accurately control the proportion of raw materials and greatly improve the production efficiency. It is also equipped with a Concrete precast machine line and Moulding equipment to ensure the stability and reliability of the product. This production line has a dimension of 7000*1000*1800mm, a weight of 2000kg, and a blue color. Moreover, it has a POSI CERTIFICATE, which guarantees that it is of high quality. With its automatic feature, this production line is highly efficient and reliable.

Customization:

Customized service for Veneer Stone Production Line from HTX:

- Brand Name: HTX

- Model Number: HTX-P-01

- Place of Origin: HENAN

- Certification: POSI CERTIFICATE

- Type: Artificial Stone Product Line

- Product Name: Veneer Stone Production Line

- Feature: Automatic

- Style: Full Auto

- Weight: 2000kg

- Keywords: Paver block making machine, Wet Cast Machinery, Concrete precast machine line

Support and Services:

Veneer Stone Production Line Technical Support and Service

- We provide technical support for the installation, testing, operation and maintenance of the Veneer Stone Production Line.

- We offer online technical support services to answer product-related questions.

- We provide on-site technical service for the Veneer Stone Production Line.

- We provide regular maintenance and repair services for the Veneer Stone Production Line.

- We offer spare parts support and replacement services for the Veneer Stone Production Line.

Packing and Shipping:

Packaging and Shipping for Veneer Stone Production Line:

When shipping Veneer Stone Production Line, the production line will be carefully packed in cardboard box, and reinforced by foam and bubble wrap for extra protection. We'll also make sure to use a suitable shipping box for each product to ensure it arrives in perfect condition.