PLC Control System Motor Wet Cast Machinery 220V 7000*1000*1800mm

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Wet Cast Machinery | Maintenance: | Low |

|---|---|---|---|

| Power: | High | Control System: | PLC |

| Size: | 7000*1000*1800mm | Voltage: | 220V |

| Highlight: | Motor Wet Cast Machinery,Concrete Dosing System 220V,Steel Automatic Wet Cast Machinery |

||

Product Description

Product Description:

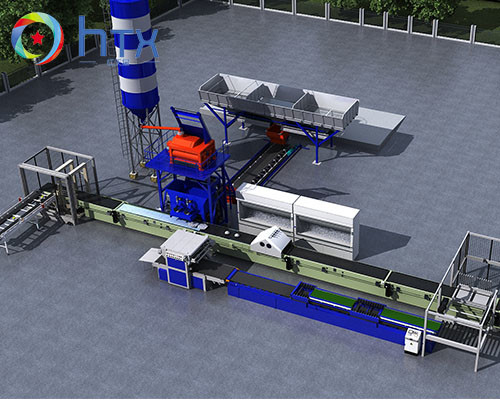

Wet Cast Machinery is a floor tile making machine designed for high-performance and accuracy. It is made of high quality steel and features a frequency of 50Hz. This automatic wet cast dosing system is a powerful and reliable machinery that is suitable for wet cast production. It is equipped with a highly responsive and accurate dosing system, allowing for precise and consistent tile production. This wet cast machinery is designed to ensure maximum efficiency and productivity with minimal wastage and downtime. It also offers a high degree of flexibility and customization, making it an ideal choice for any wet cast production.

Features:

- Product Name: Wet Cast Machinery

- Material: Steel

- Weight: Heavy

- Frequency: 50Hz

- Maintenance: Low

- Operation: Automatic

- Specialization: Plastic Paver production line, veneer stone production line, cultured stone making machine

Name Model Specification Size

(mm)

Power

(Kw)

Capacity

(m2/day)

Weight

(Kg)

Artificial stone production line HTX-P-01 Hydraulic driving;Auto feeding;

vibrating and timing feeding

7000*1000*1800 12.7 1000-1200 2000 Wet Cast Machinery HTX-P-01A Full Auto,timing feeding and vibration, weighing system; 12000*1000*2000 9.1 800-1000 2000

Applications:

HTX Wet Cast Machinery is the ideal solution for low-maintenance production of high-precision floor tiles, artificial stones, and other products. It is designed to provide a high degree of accuracy and control, thanks to its steel construction and PLC control system.

Our automatic wet cast dosing system is capable of producing a wide variety of floor tiles, artificial stones and other products with high precision, low maintenance and high power. It can be used for both industrial and artistic applications. The dosing system utilizes a PLC control system to ensure a precise and consistent output, allowing the user to maintain a high level of accuracy and control.

HTX Wet Cast Machinery is manufactured in HENAN and is designed to meet the highest standards of production. It has a low maintenance requirement and is capable of producing high-precision floor tiles, artificial stones and other products. Furthermore, its PLC control system ensures a consistent output, making it a perfect choice for industrial and artistic applications.

Whether you’re looking for a floor tile making machine, artificial stone production line, or something else, HTX Wet Cast Machinery is the perfect choice.

Customization:

Brand Name: HTX

Place of Origin: HENAN

Accuracy: High

Control System: PLC

Operation: Automatic

Maintenance: Low

Speed: High

We are proud to offer HTX Wet Cast Machinery with the latest automatic wet cast dosing system and artificial stone production line. This system offers high accuracy, PLC control system, low maintenance, and high speed. With this system, you can move your production line to the next level.

Support and Services:

We provide technical support and services for our Wet Cast Machinery. Our team of experienced engineers offer in-depth knowledge and expertise on all of our machines, enabling us to provide tailored solutions for our customers. We offer a range of services, from on-site installation and commissioning to ongoing maintenance and repair. We also provide training and technical support, to ensure that our customers have the best experience possible with our Wet Cast Machinery.

Packing and Shipping:

Wet Cast Machinery is securely packaged in our custom-made wooden crates to prevent any possible damage or contamination during shipment. The crates are designed to fit the wet cast machinery and are filled with foam material for extra protection. We also use shrink wrap to secure the machinery against any environmental conditions.

We offer worldwide shipping and can provide delivery to most locations. We will arrange for the shipment to be sent to the customer’s desired destination. All shipments will be tracked and monitored to ensure their timely arrival.