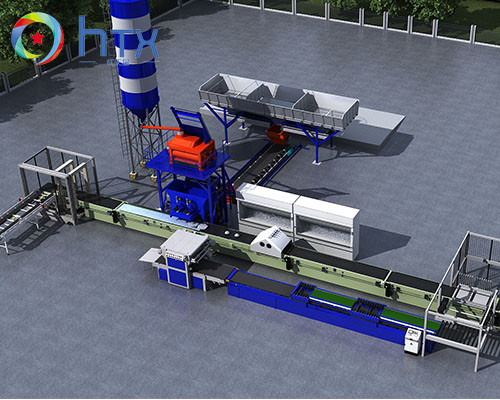

Fully Automatic Wet Material Pouring Production Line

Product Details:

| Place of Origin: | HENAN |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stone Production Line | Production Capacity: | 1000-1500m2 |

|---|---|---|---|

| Voltage: | 220V | Weight: | 2000kg |

| Feature: | Automatic | Color: | Blue |

| Dimension(L*W*H): | 7000*1000*1800mm | Whether It Can Be Customized: | Customizable |

| Local Service Location: | Kenya | Product Name: | Wet Cast Machinery |

| Highlight: | Wet Material Pouring Production Line,Automatic Wet Material Pouring Production Line,Fully Automatic Wet Pouring Production Line |

||

Product Description

Product Description:

When it comes to fully automated wet pouring production lines, here’s more information to know:

Sustainability and environmental friendliness: Fully automatic wet pouring production lines can achieve sustainability and environmental friendliness by optimizing energy use and reducing waste generation and emissions. Some production lines use energy-saving equipment and technology, such as high-efficiency mixers, energy recovery systems and intelligent control algorithms, to reduce energy consumption and carbon footprint.

![]()

Remote monitoring and operation: Some fully automatic wet material pouring production lines have remote monitoring and operation functions. Through network connections and remote control systems, operators can monitor the status, parameters and performance of the production line and make necessary adjustments and interventions. This increases the flexibility and responsiveness of the production line while reducing on-site workload and risk for operators.

Automated material handling: In addition to the automated wet material pouring process, the fully automatic wet material pouring production line can also be equipped with an automated material handling system. These systems can be used to automate operations such as feeding, material storage and cleaning, further improving the efficiency and consistency of the production line.

Innovative technologies and development trends: The field of fully automatic wet material pouring production lines is also constantly developing and innovating. For example, some new technologies are being applied to automated pouring robots, such as machine vision and artificial intelligence algorithms, to improve pouring accuracy and adaptability. In addition, sustainability and digital technologies are also research priorities in this area to achieve greater resource efficiency and smarter production.

Technical Parameters:

| Parameter | Value |

|---|---|

| Color | Blue |

| Product Name | Veneer Stone Production Line |

| Control System | PLC |

| Voltage | 220V |

| Type | Artificial Stone Product Line |

| Production Capacity | 1000-1500m2 |

| Feature | Automatic |

| Dimension(L*W*H) | 7000*1000*1800mm |

| Weight | 2000kg |

| Concrete precast machine line | Yes |

| Wall panel production machine line | Yes |

Applications:

HTX wet material pouring production line is a high end artificial stone product line made in HENAN, certified by POSI CERTIFICATE. It is designed with a full auto style and a blue color. The production line is equipped with a PLC control system, a concrete dosing system, a concrete precast machine line, and a wall panel production machine. It can help to cast concrete products in a wet environment and produce high quality veneer stone products with great efficiency and accuracy.

Customization:

HTX Wet Material Pouring Production Line, an automated and reliable solution for any wet cast machinery and veneer stone production line. Certified with POSI CERTIFICATE, this full auto artificial stone production line is made for both commercial and industrial use. Featuring a voltage of 220V, a blue color and a weight of 2000kg, this cultured stone making machine ensures a consistent production of high-quality veneer stones.

Support and Services:

We provide technical support and services for our Veneer Stone Production Line. Our customer service team is available to answer any questions you may have and to provide technical advice and troubleshooting. We provide on-site installation, training, and maintenance services to ensure your production line runs smoothly and efficiently.

We also provide round-the-clock support for our Veneer Stone Production Line. Our team is always available to help with any issues you may be experiencing. We can also help you optimize your production line for better efficiency and cost savings.

We stand behind the quality of our Veneer Stone Production Line and offer a full satisfaction guarantee. If you're not completely satisfied with your purchase, we will work with you to resolve any issues or provide a full refund.