Precast Concrete Production Exterior Natural Culture Stone Making Machine

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Culture Stone Making Machine | Voltage: | 220V |

|---|---|---|---|

| Key Selling Points: | High Productivity | Capacity: | 800-1000m2 |

| Brick Type: | Concrete Dosing System | Weight: | 2000KG |

| Highlight: | Precast Concrete Production Wet Cast Machinery,Natural Culture Stone Concrete Doser,Wet Cast Machinery 800m2 |

||

Product Description

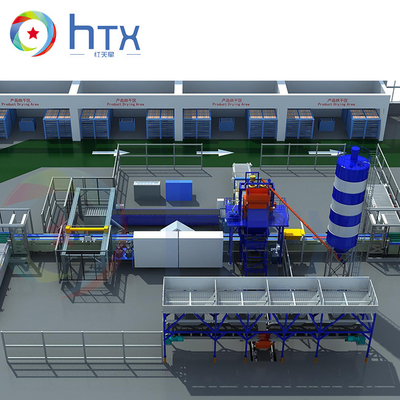

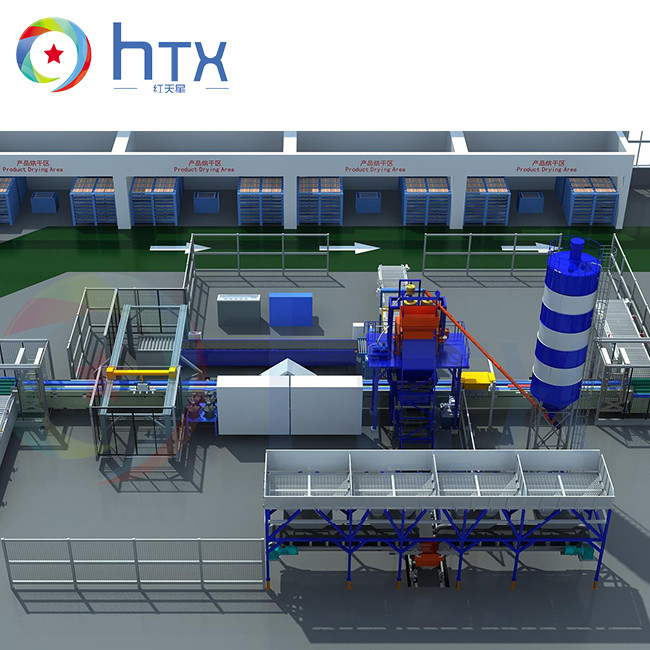

Precast Concrete Production Exterior Natural Culture Stone Making Machine

Product Description

Exterior Natural Culture Stone Making Machine has two modes of electric and hydraulic, which can be customized according to customer needs. Firstly, wet casting doser machine includes, cement silo, batching machine, auto concrete mixer, auto unloading machine, auto spray machine, auto dosing machine, auto stacking machine, pallet transfer machine, empty pallet belt conveyor, full pallet belt conveyor, air compressor, auto screen controller, pallet turning machine, demolding machine, auto packing machine and so on.

Some parts are not necessary and can be delete according to the client's needs and budget.

1. The plates are hydraulically or electrically transferred to a position parallel to the production line or to a transfer table.

2. The transfer table is transferred to a position parallel to the production line by rollers and cylinders.

3. The auto unloading machine is driven by electric or hydraulic to realize the upper and lower plates, and then the cylinder controls the gripper to grasp a pallet and transfer it to the next position.

4. Then there is the pallet turning machine. The pallet turning machine is controlled by the rotating cylinder, pressing the pallet with mold and the bricks together to another line, and then leaving the mold and the bricks. , and transport the pallet back.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Related Products

![]()

![]()

Packaging&shipping

![]()

Certificate

![]()