Flexible Container Components Wet Cast Machinery Veneer Stone Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Wet Cast Concrete Machinery | Voltage: | 220V |

|---|---|---|---|

| Key Selling Points: | High Productivity | Capacity: | 800-1000m2 |

| Brick Type: | Concrete Dosing System | Weight: | 2000KG |

| Highlight: | Wet Cast Machinery Flexible Container Components,Veneer Stone Making Wet Cast Machinery,Wet Cast Concrete Machinery 800m2 |

||

Product Description

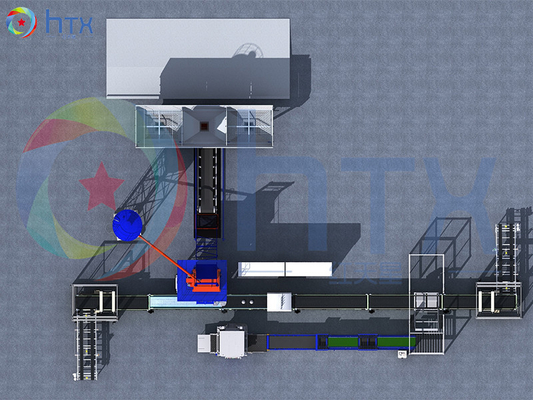

Flexible Container Components Wet Cast Equipment Veneer Stone Production Line

Product Description

Wet Cast Line, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving bricks, 3D Wall stones, terrazzo floor tile, and so on.First of all, a complete production line includes, cement silo, batching machine, auto concrete mixer, auto unloading machine, auto spray machine, auto dosing machine, auto stacking machine, pallet transfer machine, empty pallet belt conveyor, full pallet belt conveyor, air compressor, auto screen controller, and so on, we can also customize the production line according to customer needs.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Applications

Auto Concrete Wetcast System Production line advantages:More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

If want to produce good quality artificial stone some machines are necessary.Based on production capacity, clients can choose simple machine, semi-auto production line, full auto production line.

Feature advantage

Henan HTX Group Co Ltd, specialized in designing, developing, producing and marketing of artificial stone molds, paving tile molds, concrete stamp molds, pillar molds, roman column molds, and relative machines and production lines.we have more than 200 mould designs and sizes. The updated silicone material make the stone mold more durable and have good characteristic. After use again and again,our updated silicone mould still have a clear & natural texture and without any deformation.

Related Products

![]()

![]()

![]()

![]()

Packaging&shipping

![]()

Certificate

![]()