220V Wet Cast Machinery Indoor Cultured Stone Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Wet Cast Concrete Machinery | Voltage: | 220V |

|---|---|---|---|

| Key Selling Points: | High Productivity | Capacity: | 800-1000m2 |

| Brick Type: | Concrete Dosing System | Weight: | 2000KG |

| Highlight: | Cultured Stone Wall Wet Cast Machinery,Wet Cast Cultured Stone Production Line,220V Wet Cast Machinery |

||

Product Description

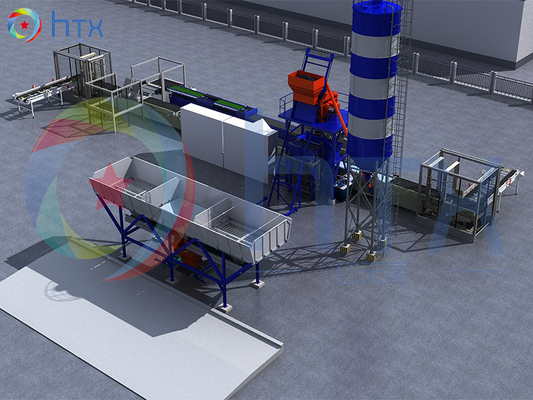

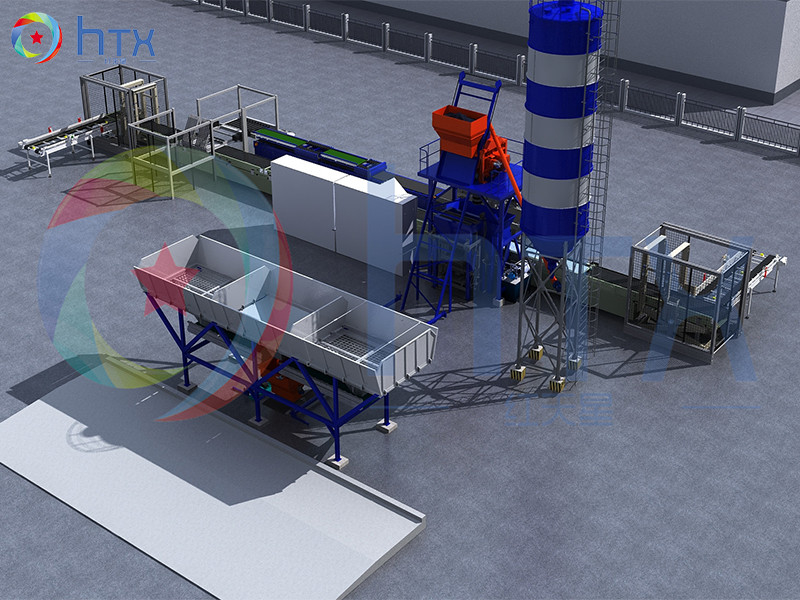

Indoor Cultured Stone Wall Concrete Wet Cast Production Line

Product Description

pre cast concrete machinery production line Including plate feeding machine, transfer table, plate drop machine, plate turning machine, spraying machine, unloading machine, first vibration, second vibration, palletizer, transfer table, plate ejector, demoulding system and conveying system. All processes require motors, and ours uses servo motors. Servo motors (servo motors) refer to the motors that control the operation of mechanical components in the servo system, and are an auxiliary motor indirect speed change device.

The servo motor can control the speed, the position accuracy is very accurate, and the voltage signal can be converted into torque and speed to drive the controlled object. The rotor speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, it is used as an actuator, and has the characteristics of small electromechanical time constant and high linearity. It can convert the received electrical signal into the motor shaft. The angular displacement or angular velocity output. It is divided into two categories: DC and AC servo motors. Its main feature is that there is no self-rotation phenomenon when the signal voltage is zero, and the speed decreases at a uniform speed with the increase of torque.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Feature advantage

Auto Wet Conrete Dosing System Production line advantages:

1.More efficient production, can achieve 800M2 Per day(8hrs)

2.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3.Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage.for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4.The auto spray painting machine, has function for mold oil sparying, stroll color painting and full color painting, also it can be turned on/off separately.

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

![]()

Certificate

![]()