Precast Concrete Equipment Wet Cast Machinery Artificial Stone Production Line

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 15000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Wet Cast Concrete Machine | Voltage: | 220V |

|---|---|---|---|

| Key Selling Points: | High Productivity | Capacity: | 800-1000m2 |

| Brick Type: | Concrete Dosing System | Weight: | 2000KG |

| Highlight: | Wet Cast Precast Concrete Equipment,Artificial Stone Wet Cast Machinery,Precast Concrete Wet Doser Machine |

||

Product Description

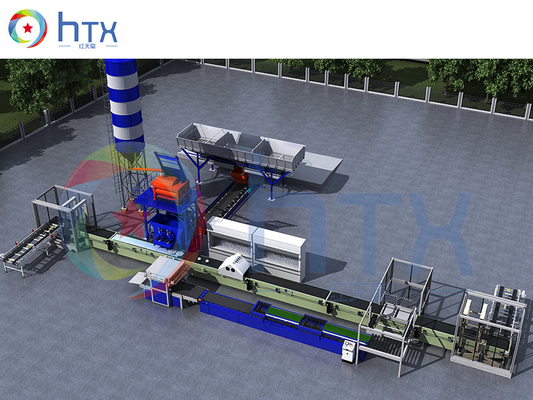

Precast Concrete Equipment Wet Cast Machinery Artificial Stone Production Line

Product Description

wet casting doser machine the silo can be set to a flat size, reduce the height, and expand the width and length, which can effectively reduce the feeding height of the entire equipment. In addition, the total height of the mixer can be controlled between 2.6-2.7 meters.If the number of bricks produced is small, it can be demolded manually, but if the number of produced bricks is large, a demoulding machine is needed to help the old quickly demould. Our machine can be adjusted according to the size of the mold, that is, all the The mold can be demolded on the demolding machine.

This is a simple configuration for our semi-automatic production line for paving bricks, we have other different configurations, we change the line to double bin batching, or the drum mixer can be replaced with a larger model mandatory mixer, depending on your Production quantity, we can do different configuration for you.

Applications

Concrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Wet Cast Machinery | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Wet Cast Machinery | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Feature advantage

Henan HTX Group Co Ltd, specialized in designing, developing, producing and marketing of artificial stone molds, paving tile molds, concrete stamp molds, pillar molds, roman column molds, and relative machines and production lines.

Especially for artificial stone, we provide one stop service, including molds, equipped with semi auto and full auto production lines, complete color ingredient and training, and special stone molds customization. Combined both traditional and new creation stone style, absorb the design idea from domestic and foreign market, we produced molds with natural stone texture.

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

Certificate

![]()