Fully Automatic Wet Cast Machinery Faux Stone Interior Wall Feeder

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 20000-80000/USD |

| Packaging Details: | Normally carton box or following customer's requirements |

| Delivery Time: | 40Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Wet Casting Doser Machine | Voltage: | 220V |

|---|---|---|---|

| Key Selling Points: | High Productivity | Capacity: | 800-1000m2 |

| Brick Type: | Concrete Dosing System | Weight: | 2000KG |

| Highlight: | Faux Stone Interior Wall Feeder,Stone Interior Wall Wet Cast Machinery,Faux Stone Wall Concrete Dosing System |

||

Product Description

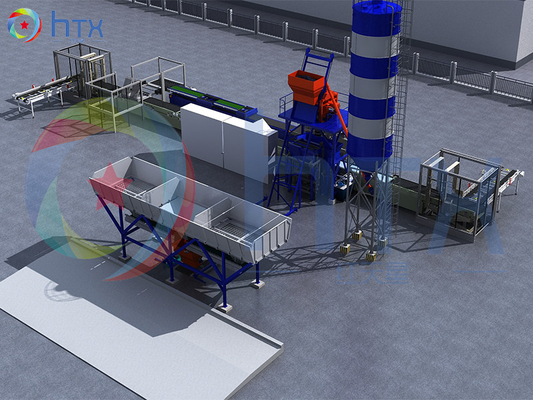

Fully Automatic Faux Stone Interior Wall Feeder Wet Cast Equipment

Product Description

wet casting doser machine includes, cement silo, batching machine, auto concrete mixer, auto unloading machine, auto spray machine, auto dosing machine, auto stacking machine, pallet transfer machine, empty pallet belt conveyor, full pallet belt conveyor, air compressor, auto screen controller, pallet turning machine, demolding machine, auto packing machine and so on.

Some parts are not necessary and can be delete according to the client's needs and budget.

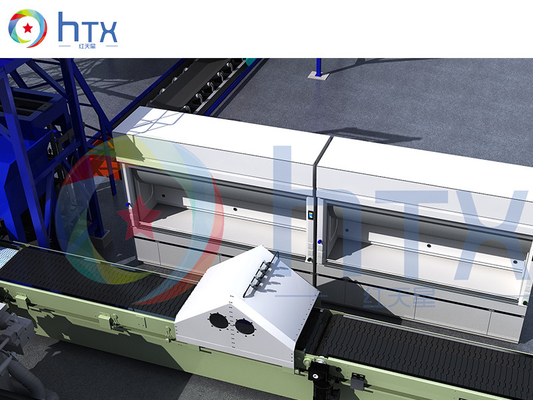

1. The plates are hydraulically or electrically transferred to a position parallel to the production line or to a transfer table.

2. The transfer table is transferred to a position parallel to the production line by rollers and cylinders.

3. The auto unloading machine is driven by electric or hydraulic to realize the upper and lower plates, and then the cylinder controls the gripper to grasp a pallet and transfer it to the next position.

4. Then there is the pallet turning machine. The pallet turning machine is controlled by the rotating cylinder, pressing the pallet with mold and the bricks together to another line, and then leaving the mold and the bricks. , and transport the pallet back.

Specifications

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

Applications

wet cast concrete machinery,adopt technoligly of automatic color pating,concrete adding ,vibrating and tranporting.It largely reduce the manpower used and imporve the efficiency.Additionally,we install 12 pieces airbrush inside machine,and can spray 4 colors at one time.It keep spraying during the silicon moulds moving on the convey belt,thus the final stone will have a gradually varied color.The stone will own a unique color which will be more popular in the market.

Feature advantage

HTX Group is offering a complete one stop production & service for customers,our system include the artificial stone molds ,3d wall panel molds ,Automatic dosing system,semi auto dosing system ,complete production procedure solution ,color ingredient training solution,workshop layout designing ,Raw material selection ,business cost analysis plan etc.

![]()

![]()

![]()

![]()

Certificate

![]()