Pre Cast Concrete Stone Veneer Production Line Automatic Artificial Palletising

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Artificial Stone Concrete Dosing Machine Wet Casting Doser Machine. |

| Delivery Time: | 50Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stone Veneer Production Line | Feature: | Automatic |

|---|---|---|---|

| Size: | 7000*1000*1800mm | Weight: | 2000KG |

| Style: | Full Auto | Application: | Interior And Exterior |

| Highlight: | Concrete Stone Veneer Production Line,Pre Cast Concrete Stone Molding Machine,Automatic Artificial Palletising Stone Making Machine |

||

Product Description

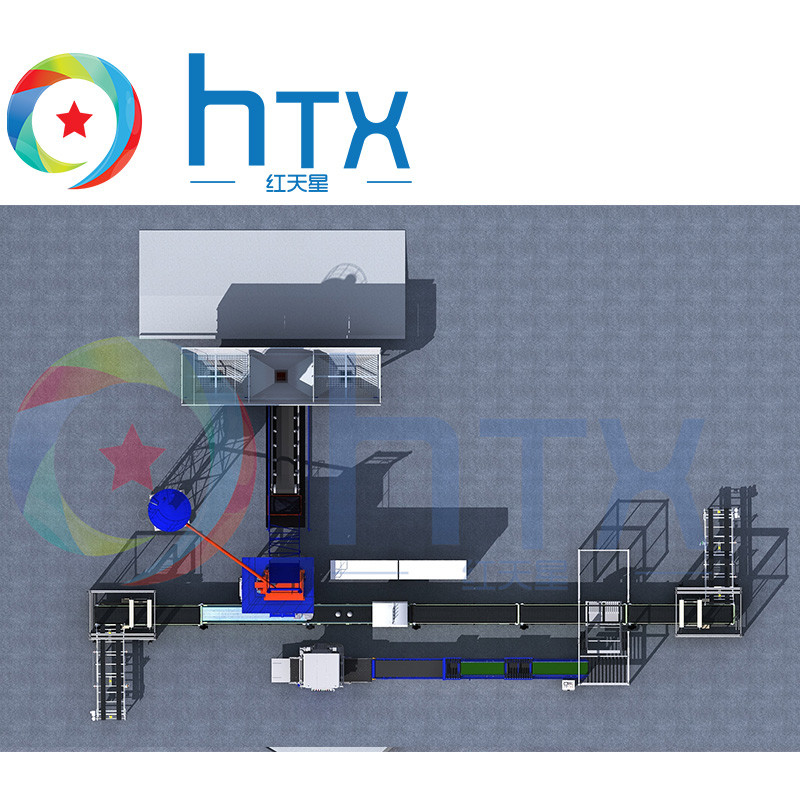

Automatic Artificial Palletising Pre Cast Concrete Stone Veneer Production Line

Auto-automatic production line uses single-silo ingredients. Your cement can be directly transferred to the mold through the silo, and conveyed through the transmission belt to improve production efficiency. The daily production output is 500-600 square meters, which is completely impossible for manual production lines.The length of the entire production line is 8 meters, which can be expanded to 15 meters according to demand, requiring a workshop space of 300-400 square meters; it has the functions of timing cutting, timing vibration, and fixed-point transmission.Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etc

oncrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Artificial Stone has become an appreciated artwork to some extent. Types of brick face for natural-like series are imitated slad, imitated sandstone, imitated serpeggiante, etc.

![]()

![]()

![]()

![]()

Our Certificate:

![]()

Want to Know more details about this product