Nice Price Concrete Sandstone Retaining Wall Making Machine Artificial Stone Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Certification: | POSI CERTIFICATE |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Carton |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Brand Name: | Concrete Dosing System | Capacity: | 1200-1500m2 |

|---|---|---|---|

| Power: | 12.7 KW | Raw Material: | Conrete |

| Application: | Buliding Construction | Feature: | High Efficiency Low Cost |

| Highlight: | Cement Concrete Plastic Paver Mould,Africa Wall Plastic Paver Mould,Concrete Roof Tile Mold |

||

Product Description

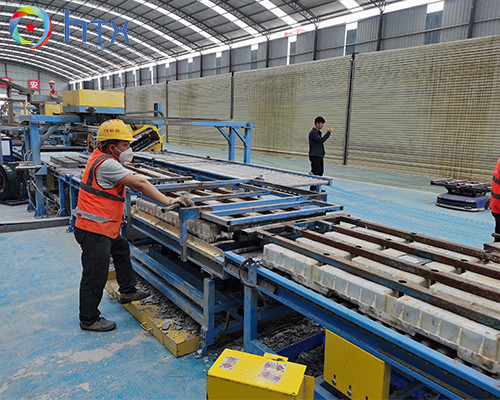

Nice Price Concrete Sandstone Retaining Wall Making Machine Artificial Stone Making Machine

1.Concrete Block Making Machine: This type of machine is used to produce concrete blocks, which can be used for constructing retaining walls. It typically involves a hydraulic or mechanical system that compacts and molds the concrete mixture into the desired block shape.

2.Slipform Paver: A slipform paver is a machine used to create continuous concrete walls with a specific shape and size. It moves along the construction site, continuously pouring and shaping the concrete to form a retaining wall. This method is often used for large-scale projects and can provide high production rates.

3.Precast Concrete Moulds: Precast concrete moulds are used to create precast concrete panels or elements that can be assembled to form a retaining wall. These moulds are typically made of steel or other durable materials and are designed to produce consistent and precise shapes. The concrete is poured into the moulds, cured, and then removed for assembly.

4.Concrete Mixer: A concrete mixer is an essential machine used to mix the ingredients of concrete, including cement, aggregates, water, and additives. It ensures a homogeneous mixture that is ready for further processing.

5.Formwork Systems: Formwork systems are not machines themselves but are crucial for creating concrete retaining walls. These systems consist of temporary molds or structures that hold the concrete in place until it hardens and gains strength. Formwork can be made of various materials, such as wood, steel, or aluminum, and can be reusable or designed for single-use applications.

6.Reinforcement Machinery: Machines like rebar benders and rebar cutters are used to process steel reinforcement bars used in concrete retaining walls. These machines aid in cutting and shaping the reinforcement bars to the required dimensions and configurations.

It's important to note that the specific machines used for concrete retaining wall production can vary depending on the scale, complexity, and design requirements of the project. Different manufacturers may offer specialized equipment tailored for specific applications.When considering the use of machinery for concrete retaining wall production, it's recommended to consult with industry professionals, manufacturers, or suppliers who specialize in concrete construction equipment. They can provide detailed information on the available machines and technologies that best suit your specific needs.

Specification:

| Name | Model | Specification | Size(mm) | Power(Kw) | Capacity(m2/day) | Weight(Kg) |

| Wet Cast Machinery | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1500 | 2000 |

| Wet Cast Machinery | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 800-1000 | 1500 |

![]()

![]()

Applications

Wet cast machinery, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for paving tile molds, 3D wall molds, wall panel molds, roadside stone molds, retaining wall molds, wall cap molds, etc.

![]()

![]()

![]()

Support and Services

Wet Cast Machinery technical support and services include:

- On-site technical support and maintenance

- Expert assistance with installation and setup

- Remote and telephone troubleshooting and support

- Periodic maintenance and inspection

- Repair and replacement parts

- Technical training and user manuals

- Upgrades and software updates