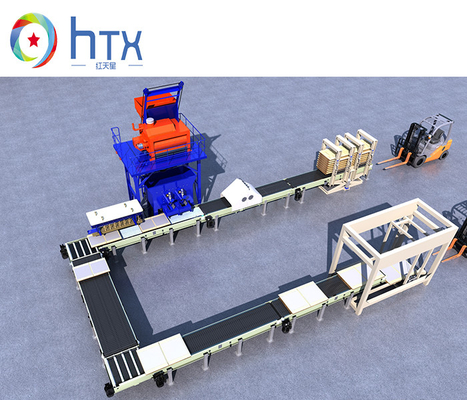

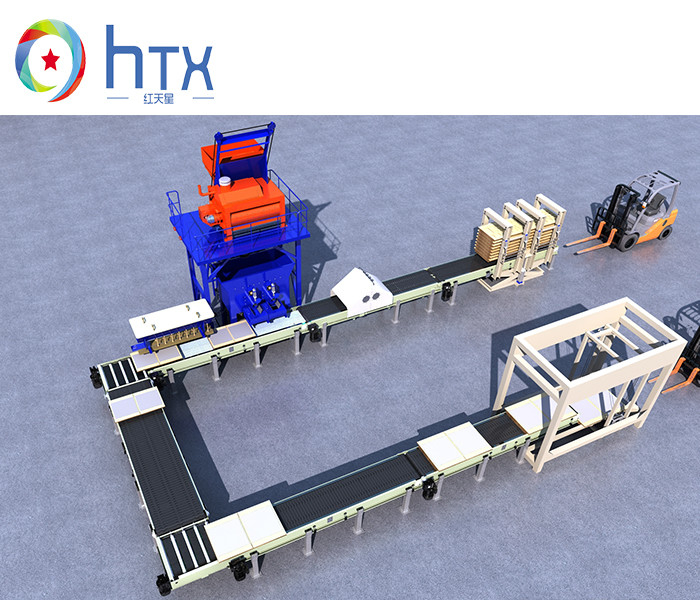

Fully Automatic Cement Concrete Paver Block Making Machine Wet Casting System

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Product Name: | Production Line For Artificial Stone Feeder Machine | Dimension(L*W*H): | 12000*1800* 2100 |

|---|---|---|---|

| Feature: | Automatic | Capacity: | 800-1000m2 |

| Color: | Blue | Application: | Buliding Construction |

| Highlight: | Cement Concrete Paver Block Making Machine,Automatic Concrete Paver Block Making Machine,Wet Casting System Concrete Paver Machine |

||

Product Description

Fully Automatic Cement Concrete faux Brick Panels Machinery Wet Casting System

Products description:

Artificial marble stone mold making machine production line has two modes of electric and hydraulic, which can be customized according to customer needs. wet casting doser machine includes, cement silo, batching machine, auto concrete mixer, auto unloading machine, auto spray machine, auto dosing machine, auto stacking machine, pallet transfer machine, empty pallet belt conveyor, full pallet belt conveyor, air compressor, auto screen controller, pallet turning machine, demolding machine, auto packing machine and so on.

Some parts are not necessary and can be delete according to the client's needs and budget.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

![]()

![]()

Related Products

![]()

![]()