Automatic Artificial Stone Exterior Walls Machine Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stone Material | Usage: | Construction |

|---|---|---|---|

| Feature: | High Efficiency Low Cost | Style: | Full Auto |

| Type: | Artificial Stone Product Line | ||

| Highlight: | Exterior Artificial Stone Production Line,Artificial Stone Exterior Production Line 1500mm,Automatic Concrete Wall Panel Machine |

||

Product Description

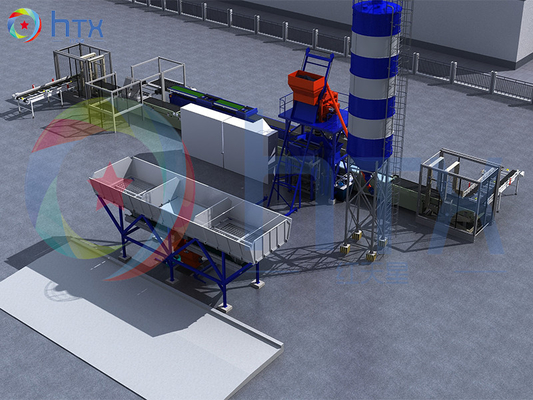

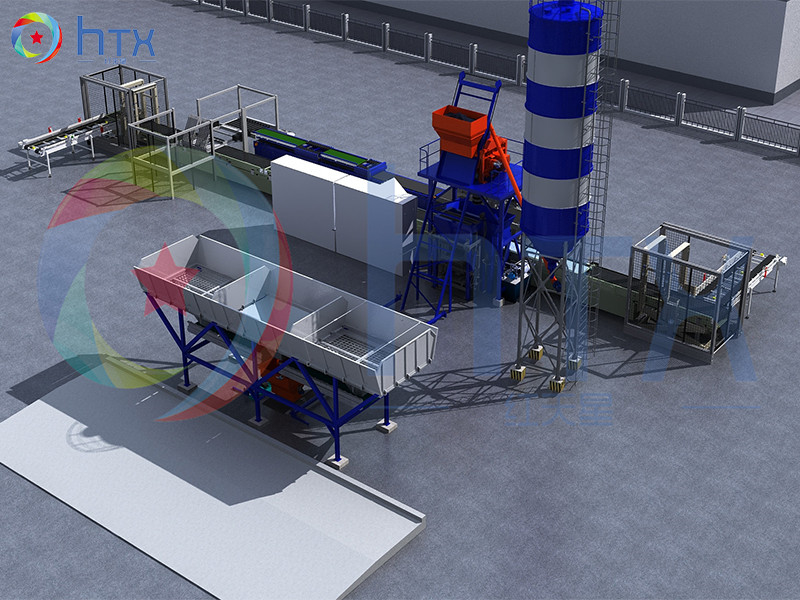

Low Investment And High Profit Artificial Stone Exterior Walls Machine Production Line

The artificial stone production line main parts are cement silo, batching machine, auto wet concrete dosing part, auto concrete fixed mixer, auto unloading and stacking machine, auto spary machine(used for add color for veneer stone), auto demolding machine, finished culture stone drying, and so on. In a whole word, from material to finished artificial stone package all full auto.

artificial stones feeding machine line production uses single-silo ingredients. Your cement can be directly transferred to the mold through the silo, and conveyed through the transmission belt to improve production efficiency. The daily production output is 500-600 square meters, which is completely impossible for manual production lines. The length of the entire production line is 8 meters, which can be expanded to 15 meters according to demand, requiring a workshop space of 300-400 square meters; it has the functions of timing cutting, timing vibration, and fixed-point transmission.

Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving bricks, 3D Wall stones, terrazzo floor tile, and so on.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()