Mixer Vibrating Faux Stone Siding Panels Mold Making Machine Production Line

Product Details:

| Place of Origin: | Henan,China |

| Brand Name: | HTX |

| Certification: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets/Month |

|

Detail Information |

|||

| Name: | Artificial Stone Making Machine Artificial Stone | Dimension(L*W*H): | 12000*1800* 2100 |

|---|---|---|---|

| Key Selling Points: | High Productivity | Feature: | Automatic |

| Size: | 7000*1000*1800mm | Capacity: | 800-1000m2 |

| Highlight: | Vibrating Siding Panels Mold Making Machine,Faux Stone Mold Making Machine |

||

Product Description

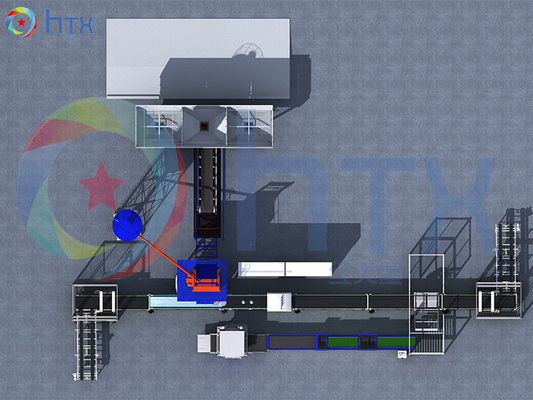

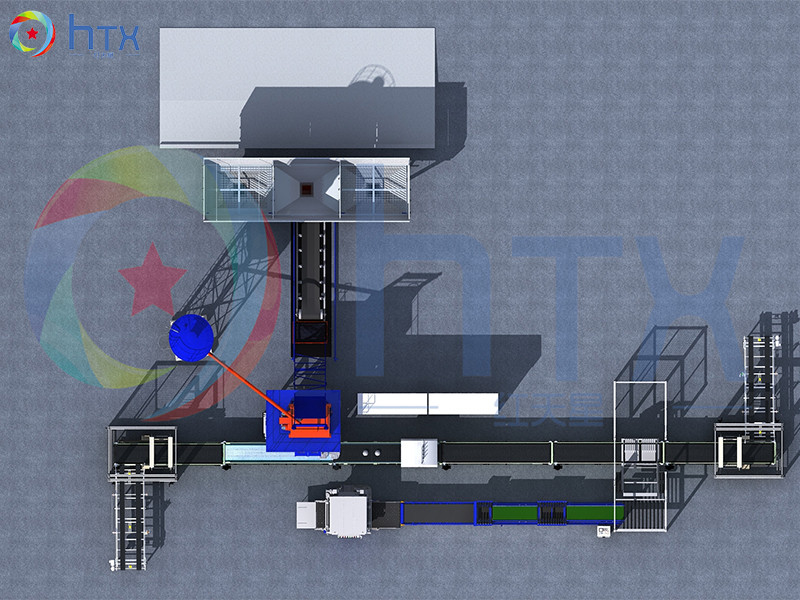

Mixer Vibrating Faux Stone Siding Panels Mold Making Machine Production Line

Paremeter

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|---|---|---|---|---|---|---|

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 1000-1200 | 2000 |

| Artificial stone production line | HTX-P-01A | Full Auto,timing feeding and vibration, weighing system; | 12000*1000*2000 | 9.1 | 800-1000 | 2000 |

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

FAQ

1) Q: Are you a factory or a trading company?

A: We are a foreign trade company integrating factories and trade. We have our own factories and overseas warehouses.

2) Q: What are the payment terms?

A: L/C, T/T, Western Union,RMB Cash.

3) Q: Do you offer formula solutions?

A: Yes,we can offer professional making solutions.You can make the color suitable for the floor tiles according to the proportion, and the color and gloss of the made tiles are better.