Wet Doser Concrete Dosing Machine Mould Turnover

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Cobblestone Paver Mold pave ways Path Maker Mold DIY Concrete Garden Slab Molds. |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Fully Automatic Stone Production Line | Key Selling Points: | High Productivity |

|---|---|---|---|

| Weight: | 2000kg | Size: | 1500*1300*2500cm |

| Usage: | Producing Artificial Stone Veneer | Feature: | High Efficiency Low Cost |

| Highlight: | Wet Doser Concrete Dosing Machine,Mould Turnover Concrete Dosing Machine,Artificial Stone Veneer Precast Concrete Machine |

||

Product Description

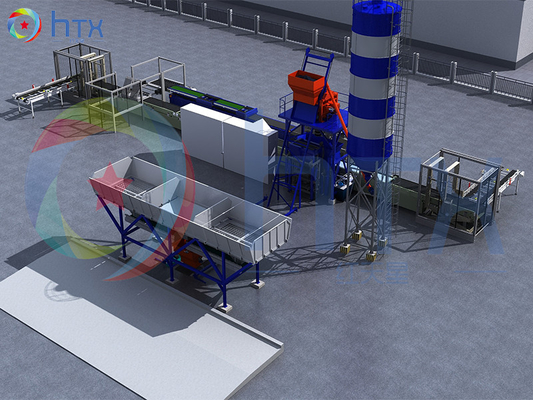

Concrete Wet Cast Mould Turnover Wet Doser Machine Concrete Dosing Machine

Product Description

Feeding machine artificial stone making Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

1. The plates are hydraulically or electrically transferred to a position parallel to the production line or to a transfer table.

2. The transfer table is transferred to a position parallel to the production line by rollers and cylinders.

3. The auto unloading machine is driven by electric or hydraulic to realize the upper and lower plates, and then the cylinder controls the gripper to grasp a pallet and transfer it to the next position.

4. Then there is the pallet turning machine. The pallet turning machine is controlled by the rotating cylinder, pressing the pallet with mold and the bricks together to another line, and then leaving the mold and the bricks. , and transport the pallet back.

Specification:

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

Related Products

Artificial Stone Mold:

Plastic paver mold:

![]()

![]()

![]()

![]()

Certificate

![]()

FAQ

Q1. Are you a Manufacturer?

A1. YES,we are a professional manufacturer specialized in plastics moulds. We have more than 20 years experience in moulds designing and manufacturing. We have our own R&D center,all the plastic moulds are factory direct.Welcome to visit our company.

Q2.Can I have my own design and logo on the products?

A2.Yes,of course.We factory offers OEM & ODM service and can customized to your specific requirements.

Q3. How to customize the molds

A3. You can send me inquiry with 3D drawing or 2d drawing ,or original sample with size ,and tell us your details requirements ,like needs to use what material,mould need to make how many cavities

Q4. Is your plastic mould in stock?

A4. Yes,We have large warehouses to store plastic products,Most of the products are in stock.

Q5. Is any discount for us?

A5. Of course,more quantity more cheaper.

Q6. How is the quality of your products?

A6. We have our own quality control procedures,and No reclaimed material used to ensure high quality.

Q7. Packing and delivery time?

A7. We can pack with your advices.About delivery, 5 days for molds in stock; 20 days for Customized molds.![]()