Cement Paver Block Making Machine Concrete Doser Feeding Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1Set |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Cobblestone Paver Mold pave ways Path Maker Mold DIY Concrete Garden Slab Molds. |

| Delivery Time: | 30Days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Artificial Stone Production Machine | Color: | Blue |

|---|---|---|---|

| Size: | 1500*1300*2500cm | Feature: | Easy To Operate |

| Power: | 37.6KW | Brick Type: | Concrete Dosing System |

| Highlight: | Paver Block Precast Concrete Machine,Concrete Doser Paver Block Making Machine,Paver Block Concrete Dosing System |

||

Product Description

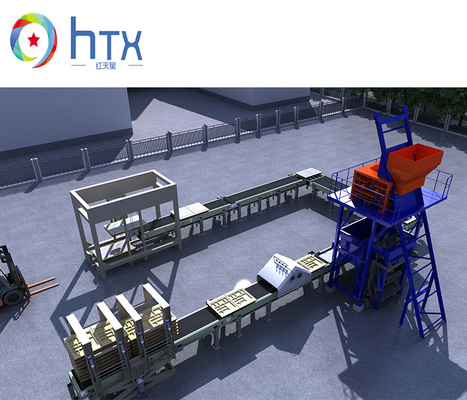

Concrete Cement Paver Block Maker Making Machine Concrete Doser Feeding Machine

Product Description

Auto unloading machine wet casting doser machine uses single-silo ingredients. Your cement can be directly transferred to the mold through the silo, and conveyed through the transmission belt to improve production efficiency. The daily production output is 500-600 square meters, which is completely impossible for manual production lines.The length of the entire production line is 8 meters, which can be expanded to 15 meters according to demand, requiring a workshop space of 300-400 square meters; it has the functions of timing cutting, timing vibration, and fixed-point transmission.Wet concrete dosing system, is suitable for different silicone molds, rubber molds and plastic molds, size range from 200*200mm to 1500*1500mm, available for producing the artificial stone both for wall and floor paving, 3D Wall panel, terrazzo floor tile, etcWe have different selling package according to the customer requirements, since each part of the line is separately and individual, the customers can buy the part which urgent needed, also it is available to buy this full production line with different steps to meet the customer requirement in a higher and cost effective way.

Specification:

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

Related Products

![]()

![]()

![]()

![]()

Certificate

![]()

FAQ

Q1. Are you a Manufacturer?

A1. YES,we are a professional manufacturer specialized in plastics moulds. We have more than 20 years experience in moulds designing and manufacturing. We have our own R&D center,all the plastic moulds are factory direct.Welcome to visit our company.

Q2.Can I have my own design and logo on the products?

A2.Yes,of course.We factory offers OEM & ODM service and can customized to your specific requirements.

Q3. How to customize the molds

A3. You can send me inquiry with 3D drawing or 2d drawing ,or original sample with size ,and tell us your details requirements ,like needs to use what material,mould need to make how many cavities

Q4. Is your plastic mould in stock?

A4. Yes,We have large warehouses to store plastic products,Most of the products are in stock.

Q5. Is any discount for us?

A5. Of course,more quantity more cheaper.

Q6. How is the quality of your products?

A6. We have our own quality control procedures,and No reclaimed material used to ensure high quality.

Q7. Packing and delivery time?

A7. We can pack with your advices.About delivery, 5 days for molds in stock; 20 days for Customized molds.

![]()