Artificial Concrete Wall Panel Machine Construction Plant Wet Doser Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | HTX |

| Model Number: | HTX-P-01 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 40000-200000/USD |

| Packaging Details: | Normally carton box or following customer's requirements for Foam CLC Lightweighted Concrete Cement Injection For House Partition And Heat Preservation |

| Delivery Time: | 30days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50Sets/Month |

|

Detail Information |

|||

| Product Name: | Wall Cladding Stone Production Line | Usage: | Producing Artificial Stone Veneer |

|---|---|---|---|

| Brick Type: | Concrete Dosing System | Material: | Steel |

| Auto Degree: | Fully Automatic | Application: | Interior And Exterior |

| Highlight: | Artificial Stone Wet Doser Machine,Concrete Wall Panel Concrete Dosing System,Construction Concrete Wall Panel Machine 1000m2 |

||

Product Description

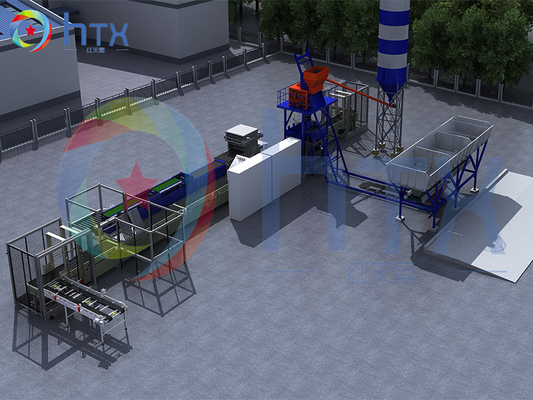

Zhengzhou Artificial Stone Production Line Plant Construction Equipment Wet Dosing Machine

The artificial stone production line main parts are cement silo, batching machine, auto wet concrete dosing part, auto concrete fixed mixer, auto unloading and stacking machine, auto spary machine(used for add color for veneer stone), auto demolding machine, finished culture stone drying, and so on. In a whole word, from material to finished artificial stone package all full auto.

If you want to start or improve your culture stone manufacturing business, pls come to us. No matter want to know how to make veneer stone, or want to increase veneer stone production capacity, or want to cut cost during culture stone production, we can help you perfectly. Henan HTX Group can provide a whole solution of veneer stone production. Including auto culture production line machine, veneer stone molds, artificial stone production training(material of veneer stone, and color formula) and finished products installation and even the factory layout design.

Concrete casting wet doser machine Product Details :More efficient production, can achieve 800M2 Per day (8hrs),Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

| Name | Model | Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

| Artificial stone production line | HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 | 12.7 | 800-1000 | 2000 |

| Artificial stone production line | HTX-P-02 | Chain drived;Auto feeding,auto vibration | 8000*1100*1600 | 4.05 | 600-800 | 1500 |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()